Rediscovering the Classic Charm of Gum-Seal Envelopes

The evolution of self-seal envelopes has brought a significant change to the world of mailing, moving away from the traditional, and often disliked, method of manually moistening envelope glue. Despite its general unpleasantness and the taste that many find off-putting, the traditional gum seal on envelopes holds a legacy filled with interesting anecdotes and wide usage.

The Underappreciated Advantages of Traditional “Lickable” Gum Seals

Originally, the gum seal was a remarkable innovation in industrial technology, addressing numerous mailing challenges efficiently. It’s important to explore both the myths and the genuine advantages of this method.

Understanding Gum-Seal Envelopes

The adhesive on these envelopes, commonly known as a gum seal, is primarily made from gum arabic. This substance, derived from the sap of specific acacia trees, is a staple in various industries due to its cost-effectiveness and versatile properties.

Gum arabic’s unique composition of polysaccharides and glycoproteins makes it an ideal edible adhesive, used in everything from confectionery to printing ink. Its ‘remoistenable’ nature allows it to dry non-sticky but reactivate upon contact with water, making it a stable and human-safe option for sealing envelopes.

Contrary to some dramatic portrayals in popular culture, envelope glue poses no health hazards. It’s designed for safety, with even the FDA overseeing its production to ensure consumer protection. Thus, fears about harmful chemicals or other dangers in envelope gum can be confidently set aside.

Pros and Cons of Gum Envelopes

Gum seals offer stability and controlled application. For mass mailing, moistening sponges or machines can efficiently seal envelopes, eliminating the need for licking.

While alternatives like latex seals or Peel ‘n’ Seal envelopes are great for personal use, they can be impractical for large-scale operations due to the waste of paper backing and their sometimes temperamental adhesive qualities.

In industrial settings, the traditional gum envelope remains a practical choice, balancing cost-effectiveness with functionality. For businesses looking at mass mailing solutions, these envelopes continue to be a reliable, less complicated option.

Conclusion

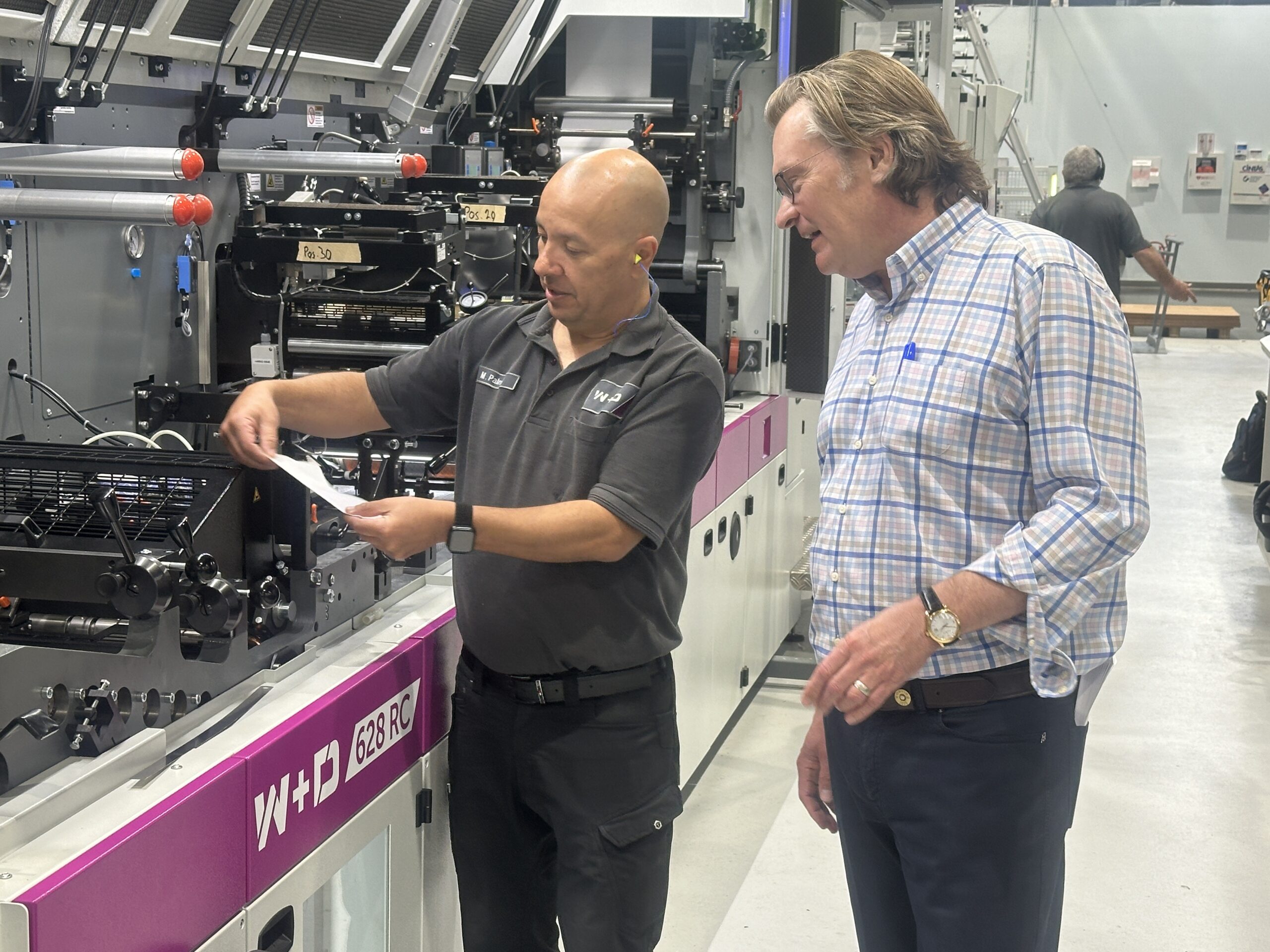

In conclusion, understanding the truths about gum-seal envelopes can help you make more informed decisions for your mailing needs. At Goelzer Industries, we pride ourselves on providing high-quality envelopes backed by our advanced printing technologies and industry expertise. If you have any questions or need further assistance, don’t hesitate to contact us. Your satisfaction is our priority.